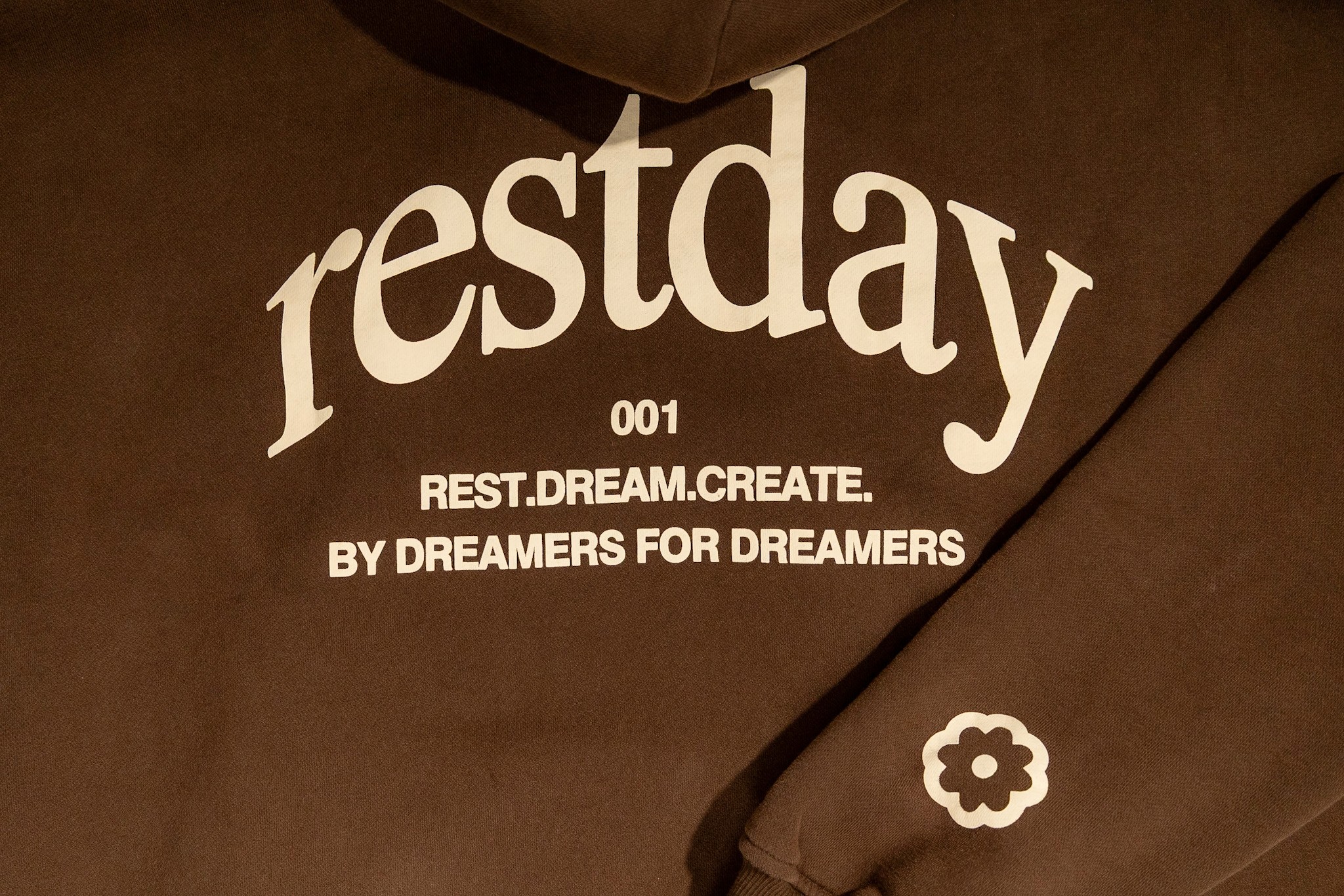

build a capsule that feels premium and wears well—without slipping timelines or margins. what was needed: a clear design pov translated into production-ready specs // disciplined sampling (proto → sms → pp) with fit + peer review // reliable sourcing and fabric testing to lock quality + handfeel // qc gates to protect delivery // packaging + labeling compliant with the identity and with ops

we formalized house codes into tech-pack standards, set a sampling cadence for full cut + sew, established custom measurements, and ran r&d on fabric and fit—then executed bulk production on a vendor-backed timeline with qc at each gate, ready to ship. a true 360° build: trims, packaging, woven labels, and hang tags; color-dye testing and lab dips; size chart and grading; handfeel and finish, including vintage washes.

creative direction & product design • technical design & full tech packs • sampling & r&d (proto → sms → pp) • sourcing, vendor liaison & costing • qa/qc, size curves & compliance • packaging system, logistics & shipping

from brief to bulk, the capsule was executed with the handfeel and fit we set out to achieve. the program delivered a complete tech-pack library, approved samples, dialed custom size charts, and vendor relationships ready to scale—plus a packaging system and logistics plan that made reorders straightforward.

key outcomes: perfectly executed production with qc at each gate; sourcing locked and costed; packaging + labeling aligned to the brand and ready for reorders. from sketch to shipment, the brand system kept standards clear.

other projects.

(2016-25©)